DURANIT® X500 catalyst bed support media - unmatched operational safety

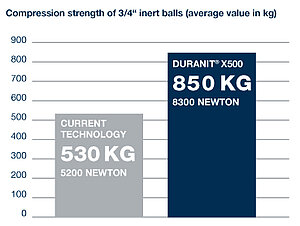

DURANIT® X500 catalyst bed support media - optimum compression strength

for maximum operational safety

DURANIT® X500 catalyst bed support media quality offers unbeatable operational safety thanks to its unequalled compression strength. It is significantly exceeding the state-of-the-art!

The very low water absorption of DURANIT® X500 is another of its great advantages for trouble-free operation. Of course the DURANIT® X500 quality, just like the well proven DURANIT® quality is also free from any type of catalyst poisons.

Ceramic raw materials: Duranit®, Acidur®, Sicafil®, Lesonit® etc. are registered brand names of different raw material qualities of VFF. The majority of raw materials used by VFF can be described as chemical-technical porcelain (CTP) of different qualities.

DURANIT® D38 inert spheres with high thermal shock resistance.

DURANIT® D38 is characterized by a significantly increased Al2O3 content of up to 38%. If the D38 inert ball is to be used together with a cover material or a Pressure Drop-Reducer, the latter can be adapted to the chemical properties of the D38 grade and also supplied with a corresponding Al2O3 content.

The DURANIT® D38 Inert ball was developed by VFF at the customer‘s request and is hardly to be found on the market in this composition and with these properties. Of course this ball quality is also available in all standard sizes at short notice.

Physical & chemical properties, average values for inert balls

| Parameters | Units | DURANIT® | DURANIT® X500 | NEWDURANIT® D38 | DURANIT® D92 Alumina ca. 92% Al2 O3 | DURANIT® D99 High Alumina ca. 99% Al2 O3 |

|---|---|---|---|---|---|---|

|

SiO2 | % | max. 80 | max. 80 | 55 - 65 | max. 7 | max. 0,2 |

| Al2O3 | % | min. 20 | min. 20 | 31 - 38 | min. 90 | ~ 99 |

| TiO2 + Fe2O3 | % | max. 4 | max. 4 | < 2 | max. 2 | max. 1 |

|

K2O + Na2 | % | max. 4 | max. 4 | < 3 | max. 0,5 | max. 0,4 |

| CaO + MgO | % | max. 1 | max. 1 | < 2 | max. 0,5 | max. 0,2 |

| Roundness | dmax / dmin | < 1,25 | < 1,25 | < 1,25 | < 1,25 | < 1,25 |

| Void space | % | 40 - 45 | 40 - 45 | 35 - 45 | 40 - 45 | 40 - 45 |

| Compression strength | kg | Exceeds all international specifications | Exceeds all international specifications | Exceeds all international specifications | Exceeds all international specifications | Exceeds all international specifications |

| Material density | g/cm3 | 2,2 - 2,4 | 2,2 - 2,4 | 2,4 - 2,6 | 3,2 - 3,4 | 3,0 - 3,6 |

| Water absorption | % | < 3 | < 0,25 | < 1 | 2 - 6 | 2 - 7 |

| BET surface | m2/g | < 0,1 | < 0,1 | < 0,1 | < 0,1 | < 0,1 |

| Mohs hardness | Mohs | ~ 8 | ~ 8 | ~ 8 | ~ 8 | ~ 9 |

| Max. application temperature | °C | 1000 | 1000 | 1000 | 1600 | 1800 |

| Expansion coefficient | 1/K | 4,7 x 10-6 | 4,7 x 10-6 | 4,7 x 10-6 | 5 x 10-6 | 6,7 x 10-6 |

| Specific thermal energy | kJ / (kg x K) | ~ 0,84 | ~ 0,84 | ~ 0,84 | ~ 1,1 | ~ 1,1 |

| Thermal conductivity | kJ / (m x h xK) | ~ 6,3 | ~ 6,3 | ~ 6,3 | ~ 8 | ~ 14,6 |

Physical properties, average value for inert balls

| Nominal size ["] inches | Diameter [mm] | Spec. surface [m2/m3] | DURANIT® Bed weight [kg/m3] | DURANIT® X500 Bed weight [kg/m3] | NEWDURANIT® D38 Bed weight [kg/m3] | DURANIT® D92 Alumina Bed weight [kg/m3] | DURANIT® D99 High Alumina Bed weight [kg/m3] |

|---|---|---|---|---|---|---|---|

| 1/8 | 3 - 5 | 1285 | 1300... 1400 | 1300... 1400 | 1300... 1400 | -- | 2000... 2200 |

| 1/4 | 6 - 8 | 500 | 1300... 1400 | 1300... 1400 | 1300... 1400 | 2000... 2100 | 2000... 2200 |

| 3/8 | 9 - 11 | 350 | 1300... 1400 | 1300... 1400 | 1300... 1400 | 2000... 2100 | 2000... 2200 |

| 1/2 | 11 - 14 | 280 | 1300... 1400 | 1300... 1400 | 1300... 1400 | 2000... 2100 | 2000... 2200 |

| 5/8 | 14 - 17 | 220 | 1300... 1400 | 1300... 1400 | 1300... 1400 | 2000... 2100 | 2000... 2200 |

| 3/4 | 19 - 21 | 170 | 1300... 1400 | 1300... 1400 | 1300... 1400 | 2000... 2100 | 2000... 2200 |

| 1 | 23 - 28 | 125 | 1300...1400 | 1300... 1400 | 1300...1400 | -- | 2000... 2200 |

| 1,25 | 29 - 35 | 105 | 1300...1400 | 1300... 1400 | 1300...1400 | -- | 2000... 2200 |

| 1,5 | 35 - 43 | 85 | 1300...1400 | *) | *) | -- | 2000... 2200 |

| 2 | 48 - 55 | 65 | 1300...1400 | *) | *) | -- | 2000... 2200 |

| 3 | 72 - 80 | 45 | 1300...1400 | *) | *) | -- | 1900... 2000 |

| 4 | 98 - 110 | 32 | 1200...1300 | *) | *) | *) | *) |

Founded in 1967, VFF very quickly developed into the largest manufacturer of tower packings and inert balls in Europe due to permanent innovations and highest quality standards. VFF has now become a globally operating company with more than 30 qualified representations. VFF products have been used worldwide at renowned licensers and end-users for processes in the chemical and petrochemical industry, as well as in other industries as substrate and covering layers for catalysts and contact masses. As a result of decades of cooperation with our customers, and through intensive work with the product, VFF is able to rely on extensive know-how. This has served as the basis for consistent further development of DURANIT® inert balls.

Quality standards and minimum lead times from the largest manufacturer of tower packings and inert balls in Europe. VFF has now become a globally operating company with more than 30 qualified representations. VFF products have been used worldwide at renowned licensers and end-users for processes in the chemical and petrochemical industry, as well as in other industries as substrate and cover layers for catalysts and contact masses. As a result of decades of cooperation with our customers, and through intensive work with the product, VFF is able to rely on extensive know-how. This has served as the basis for consistent further development of DURANIT® inert balls.

The quality of DURANIT® X500 inert balls does not just comply with all relevant international safety standards, specifications and requirements, but significantly exceeds them. This means that DURANIT® X500 inert-balls are manufactured in a process specially developed by VFF which lends the balls a compression strength which significantly exceeds the current state of the art and thereby provides customers with maximum operational safety. This high mechanical compression strength comes along with extremely low water absorption of less than 0.25 % by weight.

To keep ahead of the rest VFF places a lot of emphasis on the fact that its products are “Made in Germany”. The adherence to the stringent German and European safety and environmental requirements ensures that VFF can offer products manufactured in unison with and in consideration of its fellow men and nature. Of course, VFF is also certified acc. to DIN EN ISO 9001.

The right raw material is a very important factor for consistent quality. VFF is the only tower packing manufacturer of its kind in the world that has its own deposits of different types of raw material. This ensures consistent product homogeneity. The raw materials are thoroughly tested before during and after processing in internal and external laboratories. VFF DURANIT® X500 inert balls have a chemical composition made up from Al2O3,with a content of approx. 24 % weight and an SiO2,content of approx. 70 % per weight and are of course free from catalyst poisons.

When using catalyst supports, a high degree of operational safety through stability and homogeneity of the substrate is an important factor for the customer. The specially developed manufacturing process from VFF means that the compression strength of the Duranit® inert balls is significantly higher than that of comparable products. The mean compression strength of the 1” balls exceeds 1000 kg and provides the VFF customer with unsurpassed operational safety when filling the reactor and trouble-free operation. With the DURANIT® X500 balls VFF have succeeded, after much intensive development work, to develop a catalyst support that is far superior state of the art not just for that point.

DURANIT® inert balls, and DURANIT® X500 balls in particular, have extremely low water absorption of less than 0.25 % by weight. This only possible due to a manufacturing process developed by VFF and is a further safety aspect when using the material. The extremely low water absorption prevents liquids from penetrating far inside the balls and causing expansion e.g. due to heating, or chipping, that in turn could cause major damage in the system. This kind of risk is eliminated with DURANIT® inert balls and particularly with DURANIT® X500 balls. Of course provided that they are handled correctly on site.

Of course DURANIT® X500 inert balls are all free from any type of catalyst poisons. The careful selection and the multiple internal and external checks of the raw material, as well as the on-going checks during the processing and multiple final checks, means that undesirable catalyst poisons are ruled out. This is very important, since the catalyst poisons can reduce or eliminate the effect of the catalyst. In the case of DURANIT® inert balls the customer can be sure that they will not be confronted with this problem.

All VFF products are made according to the strict German safety standards for employees and the environment and are subjected to regular tests in the context of DIN EN ISO 9001 certification. VFF undergoes internal and external inspections in order to ensure product quality and exceeds all legal requirements for employee-safety and environmental standards.

DURANIT® inert balls have a very high degree of homogeneity when compared with competitor’s products, due to the decades of experience of VFF. The use of in-house raw materials and their careful preparation are the key to provide VFF customers with a consistently high quality. The homogeneity of VFF products at every stage of the manufacturing process is guaranteed through the use of the latest PLC-controlled processing and monitoring technology. To be able to guarantee this also in the future VFF’s motto is still: All from one company!

The unsurpassed compression strength of DURANIT® X500 balls offers the customer a high degree of safety, to avoid problems during reactor filling for example and hence save unnecessary expenses. VFF also recommends that reactor filling is carried out according to international specifications, to protect the product and system from unnecessary negative influences.

Fields of application

The processes in which the catalyst support is used, according to international specifications, comprises the whole spectrum of thermal and/or catalytic chemical transformation:DURANIT® catalyst bed support media (inert balls) and other shapes can of course be used for other applications e.g. in high-temperature filtration for the separation of solid or liquid particles from hot exhaust gases